Buteo produces high-quality wholesale granite cutting blades. The maximum cutting speed can reach more than 11m/min. Buteo best diamond blade for granite is sharp, wear-resistant and efficient. One blade is equivalent to two ordinary saw blades. Our granite cutting blade has strict error standards to ensure cutting stability.

Selected 60/80 mesh high-purity single crystal diamonds, with 300% higher resistance to crushing than ordinary granite blades.

Unique vacuum brazing technology ensures that the diamond shedding rate is less than 0.1%, while the shedding rate of traditional electroplating process is as high as more than 5%.

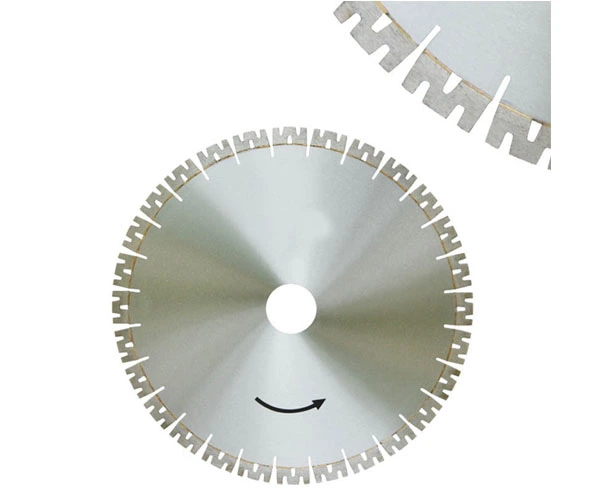

Through five-axis CNC laser dynamic balance correction, the vibration value of the granite cutter blade is strictly controlled within 0.8mm/s.

The vibration value of the manual leveling method of ordinary granite cutting blade manufacturers exceeds 2.5mm/s, resulting in rough and broken edges on the cutting surface.

The 3D fluid mechanics heat dissipation slot design keeps the temperature of the granite cutting blade stable below 180℃ when it is working continuously.

Compared to ordinary granite cutting blades, which often exceed 260℃ due to poor heat dissipation, causing thermal damage and failure of diamonds.

Equipped with self-developed cutting parameter AI algorithm, the cutting plan is automatically optimized according to the hardness of the stone.

Ordinary granite cutting blade manufacturers only provide paper instructions, which cannot achieve precise process matching.

A blade with a 50% concentration can cut approximately 30% more linear meters than one with a 40% concentration (measured data).

There are two scenarios:

▸ Dry cutting - We recommend a 3-minute cooling break every 20 minutes (with our cobalt-based heat sink, it can last 40 minutes);

▸ Wet cutting - A water pump is used for continuous cooling, and continuous cutting for 8 hours without softening is required."

① Laser code traceability - Our wholesale granite cutting blades can verify the production batch/welder number for each blade.

② Two blades per box for trial cutting - You can randomly test the blades. If the efficiency does not meet the standard, the entire box will be returned.

③ If the error exceeds 5%, double compensation will be paid based on the number of blades.