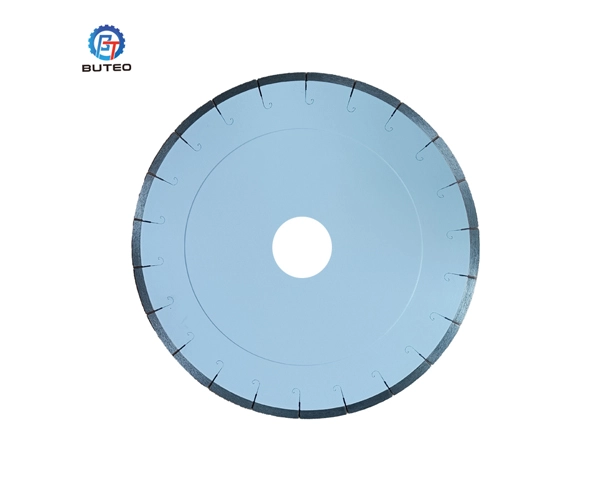

Dekton saw blade: precision cutting of modern surfaces

Unleash the full potential of your cutting projects with our high-quality Dekton saw blades, designed specifically to tackle the unique challenges of cutting Dekton. This blade is perfect for professionals, combining advanced technology with exquisite craftsmanship to provide flawless results every time. Enhance your customers' cutting experience with precision, durability, and superior performance blades.