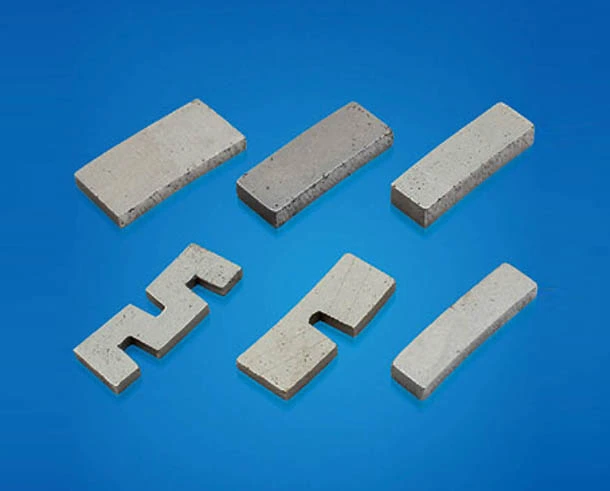

Granite cutting segment are small, specialized cutting tools used in diamond saw blades. These segments contain synthetic or natural diamond particles, offering exceptional hardness and durability for precise and efficient cutting of granite slabs, countertops, and tiles in the stone fabrication industry. We are a professional granite cutter segment supplier, dedicated to providing you with quality products and services. We believe that through our granite segments, you will definitely achieve more brilliant achievements in your field!

Engineered for extreme durability, our granite cutter segments deliver smooth cuts with minimal wear, ideal for high-volume stone processing.

Optimized for CNC and bridge saws, these diamond segments for granite cutting ensure clean edges and extended blade life, reducing downtime.

Built with high-grade diamond grit and advanced bonding, our granite segments withstand heavy-duty cutting without chipping or premature wear.

Need tailored specs? We offer granite cutting segments in multiple bond styles and concentrations to match your exact machinery and granite type.